The Laidig Fluidized Screw system is ideal for high-volume storage and unloading of fluidizable materials, such as cement, fly ash, talc powers and much more.

The Fluidized Screw is designed to eliminate the need for costly fully aerated floors. It integrates the best of two proven technologies — the rugged mechanical screw with an efficient air-gravity conveyor system — for a cost effective, energy efficient, reliable solution.

How does the Fluidized Screw Work?

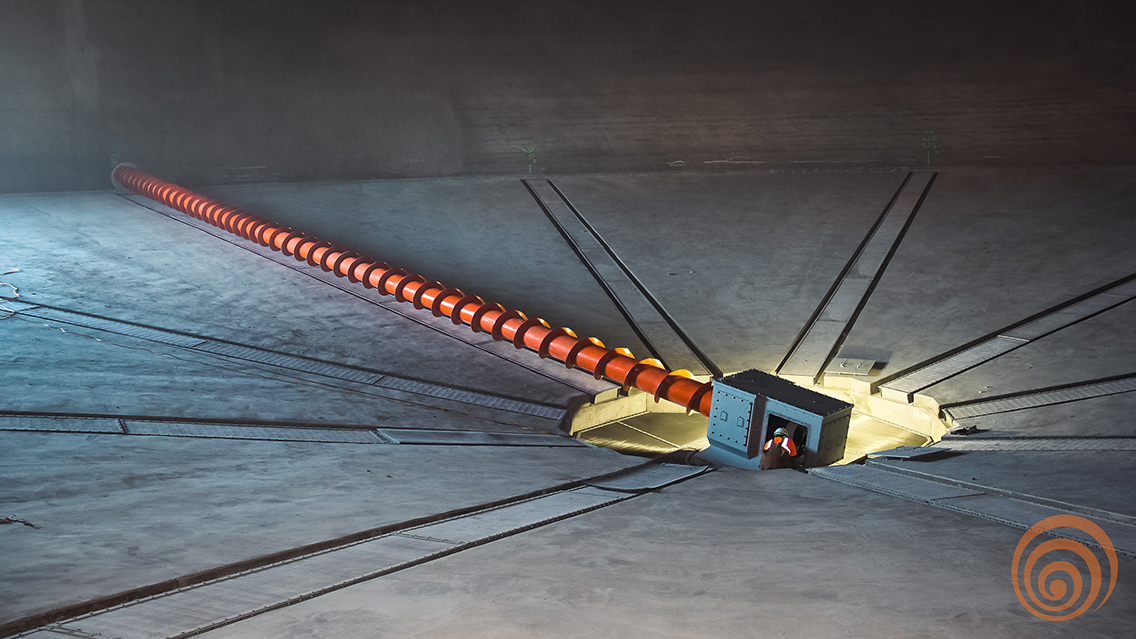

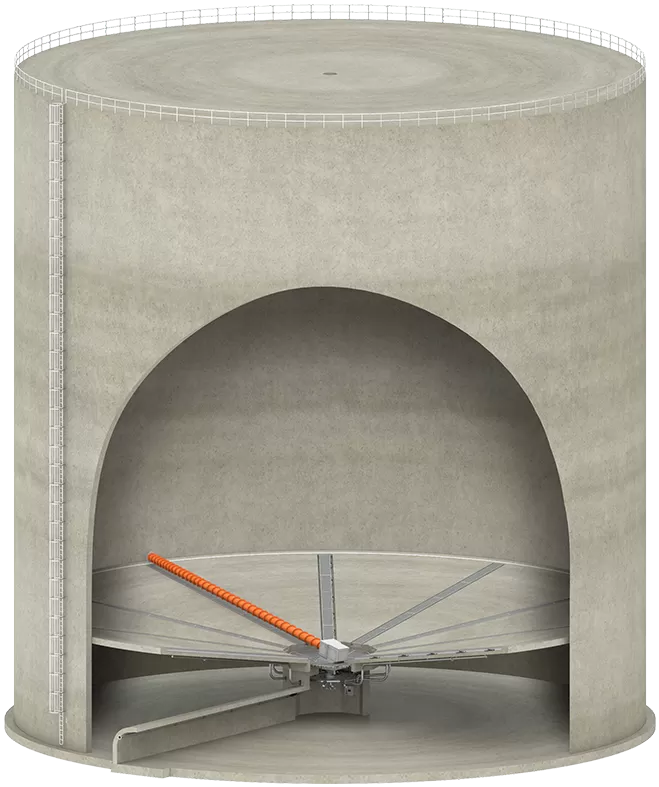

The Fluidized Screw System is comprised of two technologies that work seamlessly together for maximum effectiveness.

Air gravity conveyors

The dome is configured with an aerated center hub and radial spokes that empty a large percentage of the total stored material through proven air conveyance technology. Intelligent control systems sequentially activate air-gravity zones to empty the dome in an even and controlled manner.

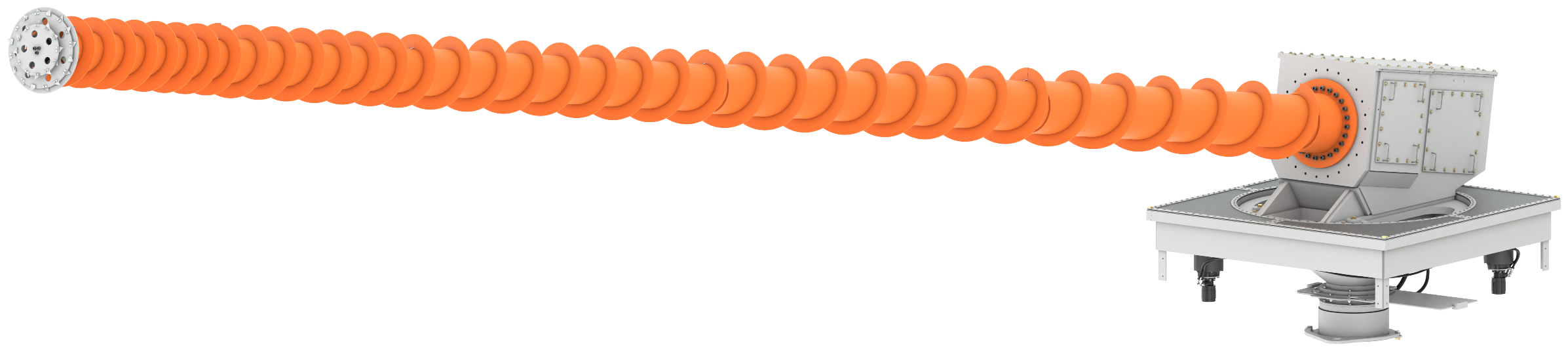

Mechanical Screw Reclaimer

After all the air gravity conveyors have run, the mechanical screw operates to break down and clean out the remaining piles of material in the dome.

The Laidig Guarantee

"If we design and install your storage and reclaim system, we guarantee it will work."

Up to 190'

Diameter

Eliminates Costly

Full-Aerated Floors

Zero-Entry

Cleanout

Reversible

Sweep Auger

Heavy-Duty

Industrial

Application

Energy-Efficient Solution

Fully Automated

Operation

Lifetime Technical Support