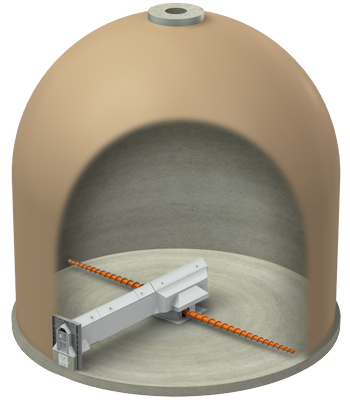

Model SM933

The Laidig Symetrix offers superior performance and dependability for large applications with high-density or abrasive materials.

Laidig’s Symetrix system is engineered to provide completely automated, near-total cleanout, encouraging first-in-first-out material distribution for processing to strict quality-control standards.

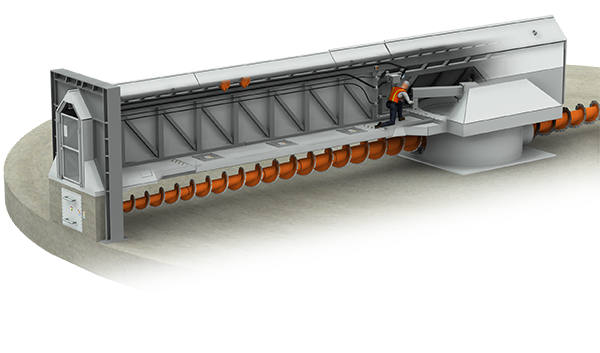

The beam bears the material load and shields the auger from high compressive forces during both the fill and subsequent operation making the Symetrix the system of choice for high-density materials. Coal, dense powders, and heavy or coarse granular materials are ideal applications for the Symetrix.

Benefits of the Symetrix

The Symetrix provides an access beam which spans the diameter of the storage vessel. This beam offers complete access to all serviceable components of the Symetrix, even under a full head-height of material! Serviceable components include motors, gearboxes, reducers, and the auger cutter blades. When positioned under the beam, the entire auger can be removed from the full silo.

Laidig’s Symetrix reclaim system is designed for durability and longevity. Its tapered auger design greatly increases efficiency of material conveyance while reducing wear on the components. Additionally, augers can be fully hardfaced to achieve maximum wear resistance.

The Laidig Guarantee

"If we design and install your storage and reclaim system, we guarantee it will work."

Up to 110' Diameter

Access Service

Components in a

Full Silo

Fully Automated Operation

Zero-Entry

Unloading