Durable, Rugged Reclaim Since 1961.

Becoming the world leader in bulk material storage and reclaim doesn't happen by accident. For us, going global is the result of a careful plan that prioritizes problem solving. Laidig has expertly engineered and installed thousands of reclaim systems, serving dozens of industries across almost every continent, and we are not stopping there. We are committed to your business as if it were our own — because your success IS our success.

Laidig Builds Reclaim Systems That Do the Work For You.

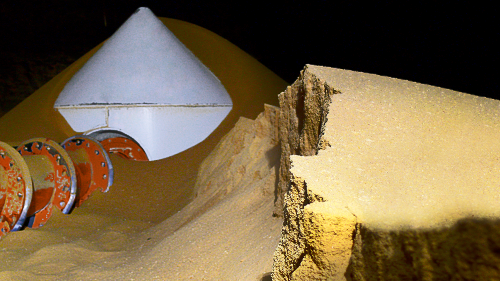

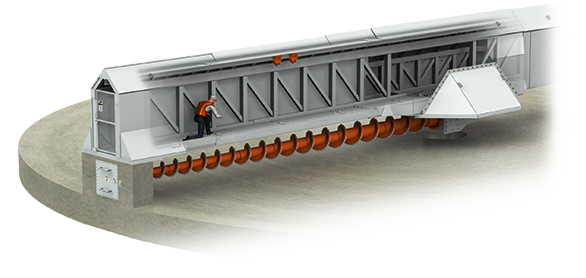

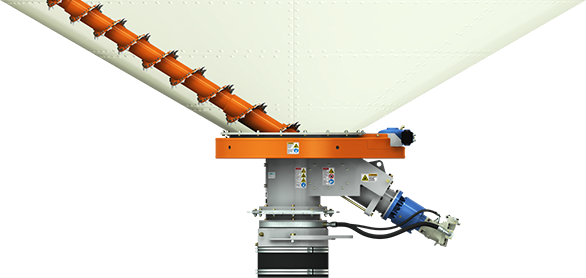

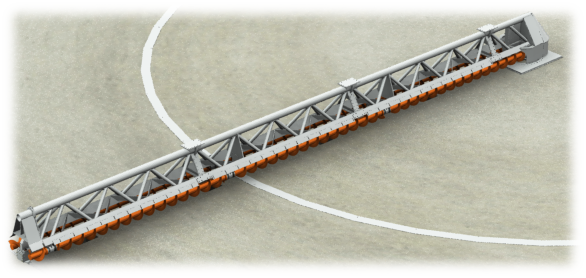

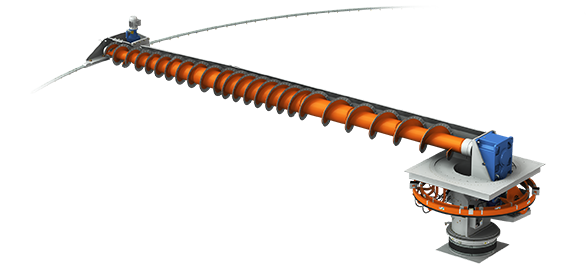

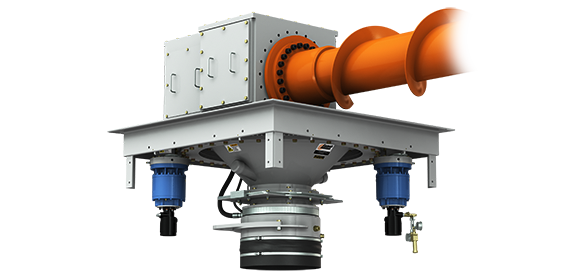

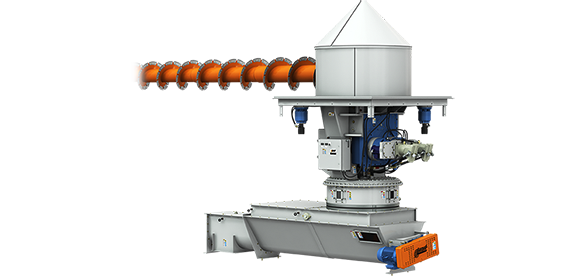

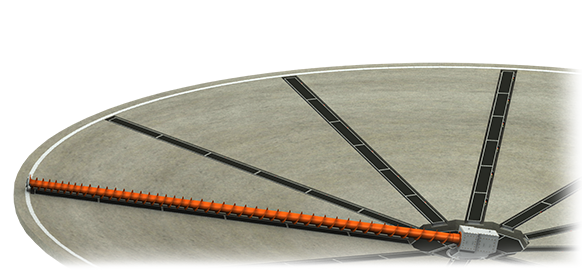

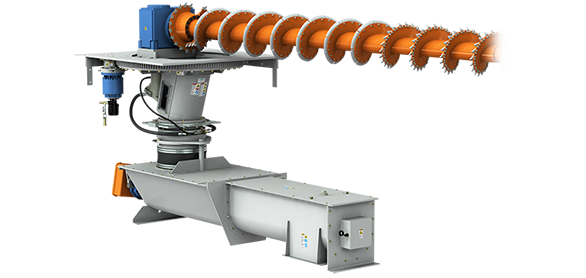

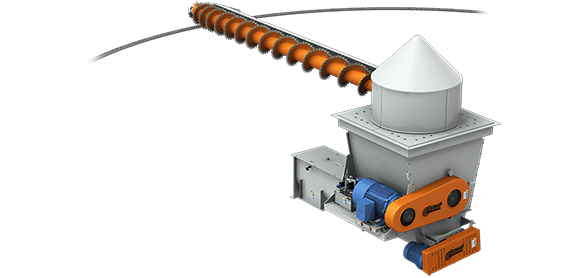

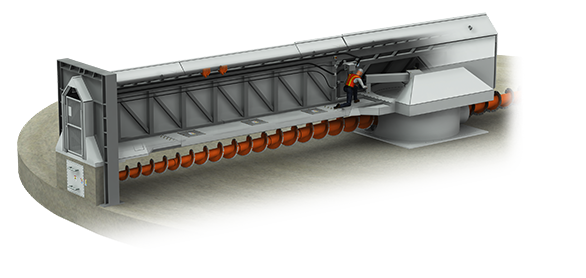

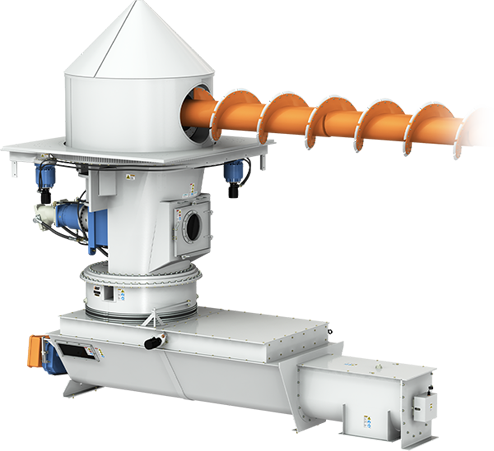

Laidig excels in providing customized solutions for handling materials with poor material flow characteristics or other special requirements. We are a global leader in designing and building reclaimers to automate the unloading of dry bulk materials. The reliability and sophistication of Laidig's reclaimers have proved to be invaluable for industrial, process-driven applications in industries such as food processing, meals, pulp & paper, wood pelleting, biomass, power, biofuels, ethanol, mining & minerals, cement, and many more.

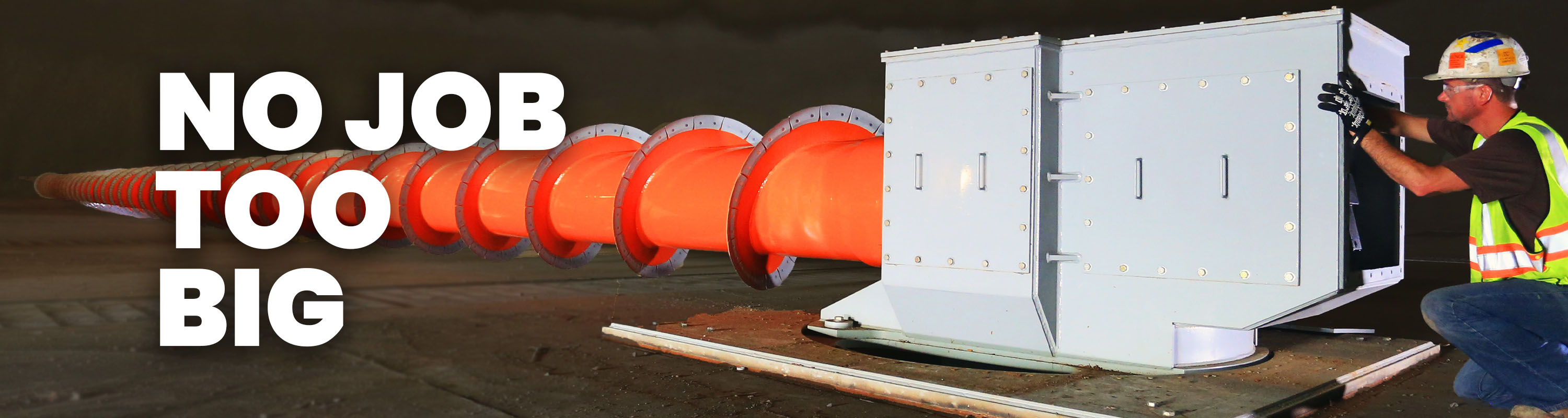

Designed, Engineered, and Manufactured Specifically For Your Needs.

Laidig designs, engineers, fabricates, installs, and services custom storage and reclaim systems for silos, domes, and open piles to provide complete “turnkey” material handling systems. Laidig's highly qualified team has the knowledge and expertise necessary to provide solutions for some of the most difficult material handling and silo unloading challenges. Our rugged systems provide aggressive reclaim of non-flowable and semi-flowable materials through consistent, first-in-first-out (FIFO) operation. Laidig reclaim systems can be installed in both flat and cone bottom structures, and are capable of handling a wide range of storage and output capacities.

Ready to Learn More?