Cantilever

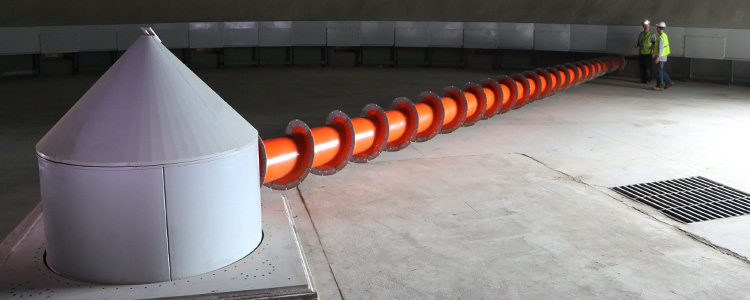

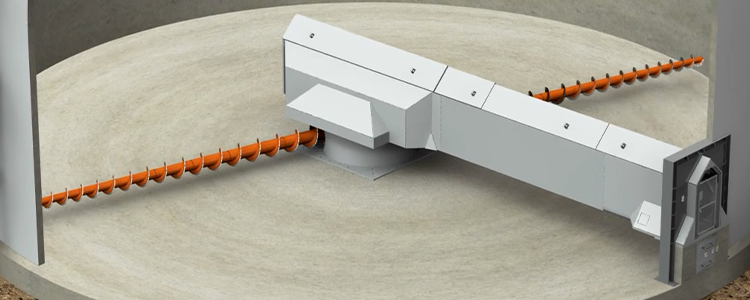

The Cantilever storage and reclaim systems are designed to accommodate a wide range of material applications in flat-bottom vertical storage structures. Laidig’s Cantilevers are either hydraulically or electrically driven and may be designed with single or dual augers, depending upon the application.Cone-Bottom

Our Cone-Bottom systems provide fully automated reclaim of materials with moderate-to-poor flow characteristics. It offers unique access to all serviceable equipment, allowing for zero-entry maintenance even in a full silo. Systems can be designed for 30, 40, 45, and 60-degree hoppers.CleanSweep

The CleanSweep system is ideal for high-volume storage and reclaim of semi-free-flowing materials. The CleanSweep system combines multiple draw downs in the floor with a wheel-supported auger. It offers a fully-automated clean out solution without the need for personnel entry. The unique reversing capability offers flexibility.Track-Drive

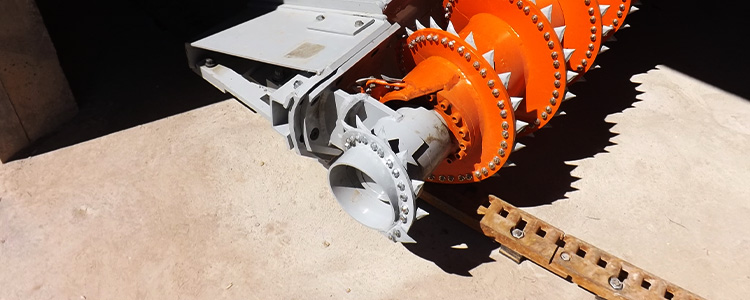

The heavy-duty Track-Drive reclaim systems are designed for automated, continuous operation under the most challenging conditions. When higher-volume delivery is required, or when handling materials with poor flow characteristics, track-driven reclaim systems are often the optimal solution.X-Traktor

Laidig has engineered the X-Traktor from the ground up to provide unparalleled performance and flexibility in the largest-possible diameters for materials with poor flow characteristics. The X-Traktor provides fully-automated delivery at high discharge rates from large-diameter domes or super silos.DOMinator

The unique design of the DOMinator extends the diameters of Track-Drive systems beyond what was previously possible, providing automated reclamation of hard-to-handle materials in the most challenging environments. This system shields the track-advance drive components from the material in a perimeter access area.Fluidized Screw

The Fluidized Screw offers automated storage and reclaim of fluidizable bulk materials like cements and powders. It incorporates two technologies, combining an efficient air-gravity conveying system with the dependability of a rugged mechanical screw conveyor, for a system that can handle hard pack with confidence.Planetaire

Laidig's Planetaire is ideal for handling abrasive and high-density materials like minerals, dense powders, and coal. Its special beam-supported design allows for complete service and accessibility of all reclaim components. The beam protects parts from extreme material forces, keeping them in a low-load environment.Symetrix

The Laidig Symetrix offers superior performance and dependability for large applications with high-density or abrasive materials. The beam bears the material load, sheilding auger from high compressive forces, making the Symetrix the system of choice for things like coal, dense powders, and other granular materials.

Frequently Asked Questions

Our reclaim systems improve process efficiency across the board:

- The automation our unloaders provide can reduce labor costs and wasted downtime.

- The safety our solutions bring keep personnel out of the storage structure.

- The flexibility our technology offers opens up options for processing, purchasing, and maintenance.

- The reliability our reclaimers produce means your operation can stay running at pace with today's demands: 24/7/365.

Not only can Laidig customize your machinery, we will customize it. We don't just make machines, put them on a shelf, and then ship them out when we get an order. A tailored system, designed for your exact needs, is simply part of the package when you buy Laidig.

We have a dedicated engineering team of 20+ experts to design your solution, a large manufacturing team and state-of-the-art facility to craft and assemble the components, and construction crews and service technicians to install it for you—all to the specs you expect.

The beauty of our technology is that it's applicable to many different important industries. We serve some of the biggest companies on the planet because they know the reliability a Laidig reclaimer provides brings the stability they need to keep their operations running.

Some of the industries we serve include:

- Grain and oilseed processing

- Feed and grain

- Flour milling

- Ethanol

- Biomass

- Pet food

- Chemicals and powders

- Click here for more

Laidig has provided solutions across the globe—almost every continent, in fact!

We have a major presence inside the plants of some of the world's biggest companies. Brands you know and use every day trust Laidig to make sure their process keeps moving.

We also have dedicated sales professionals for areas outside the United States who only help international customers. We love working with our partners around the world and we pride ourselves in our ability to serve everyone.

After your system is installed, we don't leave you hanging. We keep your project on file forever and can help you work through any future issues with the same level of expertise you experienced when you first bought your equipment.

Our dedicated service professionals take their jobs seriously, because downtime is wasted time for so many of the industries we serve. Our after-the-sale service is a serious asset to your team.

Laidig specializes in screw-type bottom reclaimers that are designed to start and operate under a full material load.

The screw/auger rotates on its own axis, which pulls material toward the center of the silo floor. From there, the material flows down through a center chute under the floor, and into a discharge auger or conveying system. The material then continues to the next stage in the process.

Our systems enable you to store more hard-to-handle materials, in larger quantities, for longer periods of time, since they eliminate so many of the problems that can happen with large-scale storage and unloading.

If you deal with storing hard-to-handle materials in large volumes, you know how difficult it can be. So many problems can and do arise across several industries as they advance to keep up with a growing world. Laidig has identified these issues, and has designed a family of reclaimers to solve the following material problems:

- Bridging

- Rat-Holing

- Densification

- Compaction

- Mold, spoilage, and insect infestation

- Silo implosion, collapse, or other failure