Whether we're perfecting our systems structurally or developing brand new technology, innovation is in our blood.

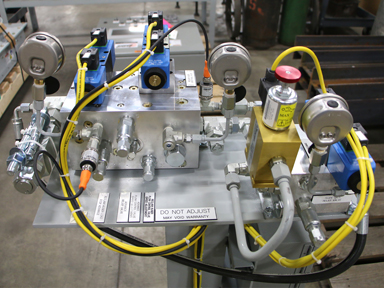

Laidig has developed state-of-the-art Smart Controls to ensure that your equipment operates efficiently.

Our Smart Controls are critical components to your reclaim system, continually monitoring your components and safeguarding your equipment by providing alerts when potential issues arise. Remote access is also available in order to track and monitor your system as necessary.

Laidig develops a complete, customized control system for each application, including the main control panel, the Laidig Machine Interface™ (LMI), which contains the programming logic to intelligently and safely control the Laidig reclaim system.

Laidig’s LMI™ incorporates state-of-the-art PLC control systems and interface technology to dynamically control the reclaim system in variable load environments. The LMI™ provides fully automatic operation of the system, properly controlling the reclaimer rotation, reclaimer advance rate, and discharge rates, while also taking into account the dynamically changing load conditions. The LMI™ also provides manual controls for jogging and maintenance operations, and is located in close proximity to the reclaimer to allow visual and audio feedback to the operator during manual operations.

The LMI™ is designed to allow easy integration with the customer’s main control panel. Full monitoring of all system functions is accessible on the customer’s network via ethernet. The ethernet access allows remote monitoring and programming support, along with data logging.

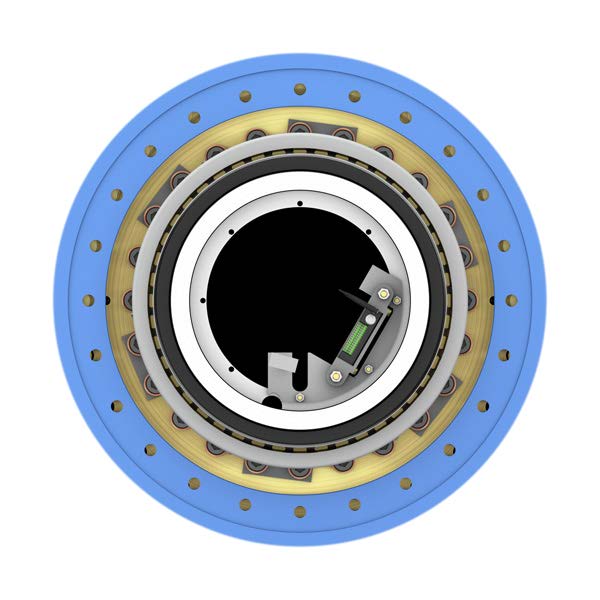

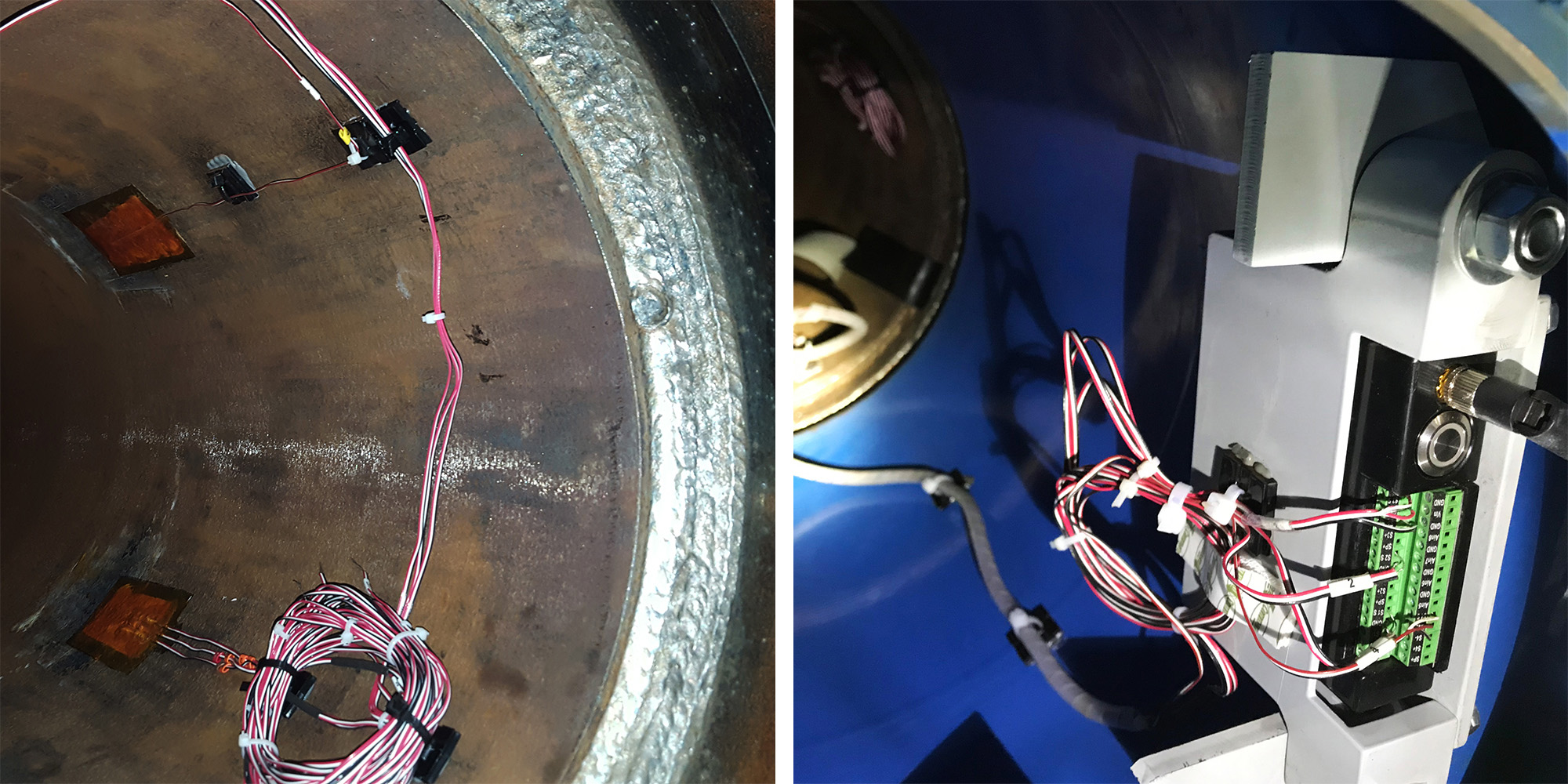

Internal Measurement Feedback (IMF) Auger System

(U.S. Patent 10,981,730)

- Works with LMI™ to use real-time feedback in order to optimize system performance by minimizing auger loads

- Helps protect critical components from experiencing life-reducing loads caused by misadjustment or improper operation

- Can significantly improve auger drivetrain life by reducing downtime and maintenance costs over the life of the reclaim system

- Enhances the reclaim system to operate at peak efficiency while providing proactive protection

- Optimizes the efficiency of the reclaim system and protects against adverse load conditions

- Improves reliability to help ensure minimal downtime and maintenance costs over the life of the reclaim system

Other Patented Technology

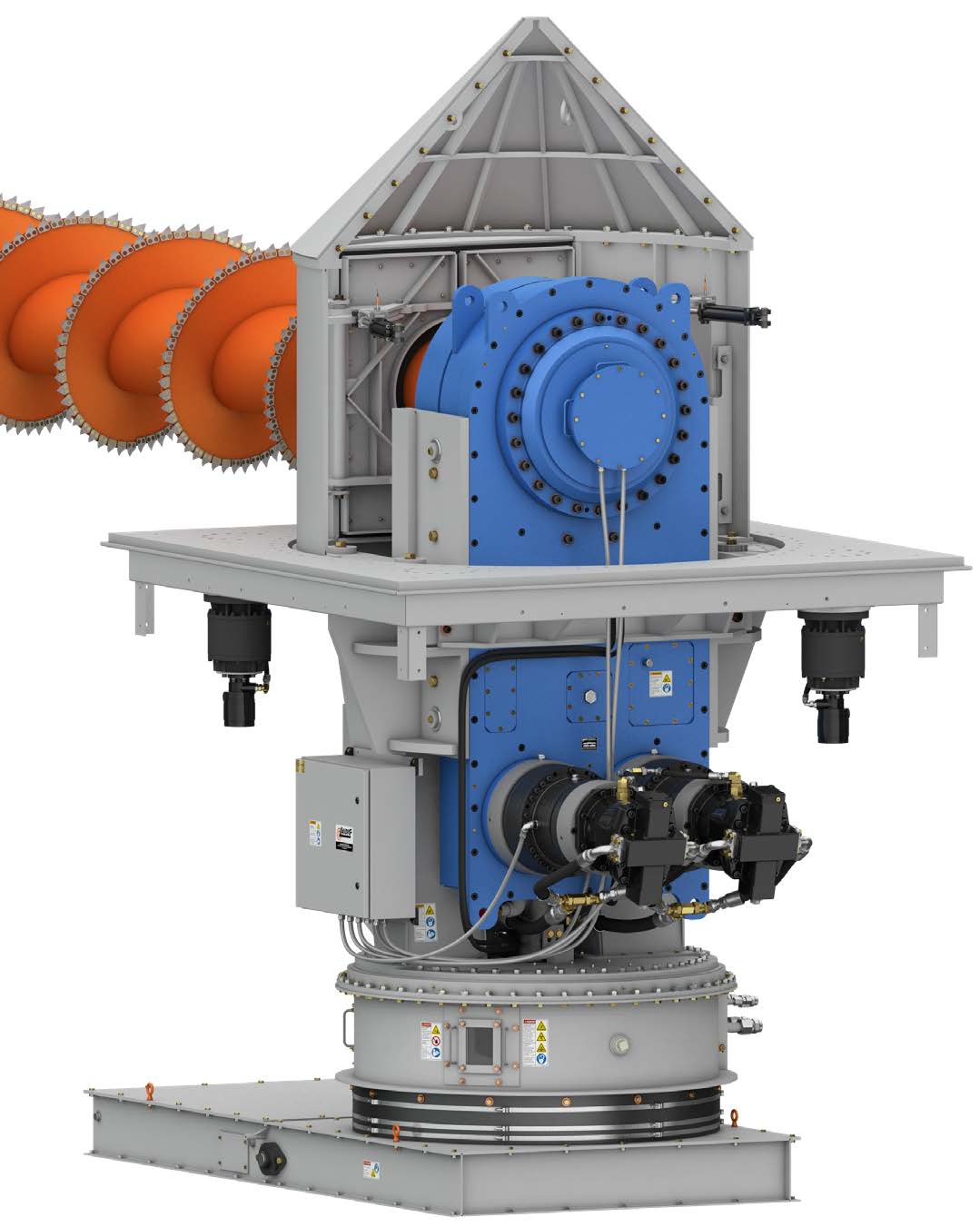

Oscillating Wheel Auger Support

- Oscillating motion and knives break up compacted materials at the silo wall

- Motion can minimize advance loads and decrease auger deflection

- Option serves as an interchangeable upgrade to the existing auger support wheel

- Can work for storage diameters of up to 200' (61 M) with Laidig's rugged CleanSweep™ design

- Keeps your operation running and your personnel out of the silo

- U.S. Patent 10,160,605

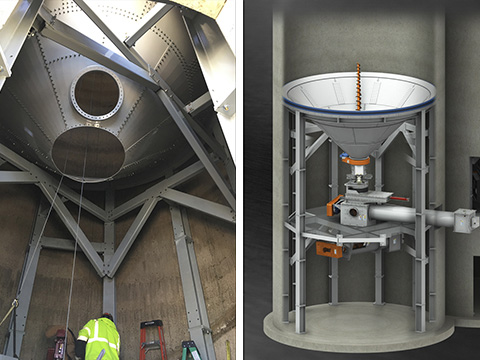

Independent Floor System

- Laidig can design, construct, and erect a patented free-standing floor within your existing structure

- Can work for cone-bottom or flat-bottom silos

- Flexible, cost-effective option for older or unused silos

- Eliminates unnecessary material loads not initially considered in original silo design

- Extends the life of your existing structure

- Ensures a solid, safe installation base for your reclaim equipment

- U.S. Patent 10,766,719