Laidig excels in innovative, effective designs to store and reclaim biomass materials with special handling requirements.

Biomass materials can be difficult to store and handle with a variety of challenges that include: ability to flow, particle size, particle types, and moisture content. Our machines can be designed for applications like wood chips, wood pellets, wood shavings, sawdust, and hogged bark.

Laidig reclaim systems provide solutions to silo-bridging problems that occur with rugged, fibrous or hard-to-handle materials associated with biomass applications. Laidig reclaim systems help create mass flow - enabling near-total clean out - while maintaining a first-in-first-out (FIFO) inventory control.

Laidig Biomass Reclaim System Applications are designed for:

- Wood-for-energy

- Wood-for-process

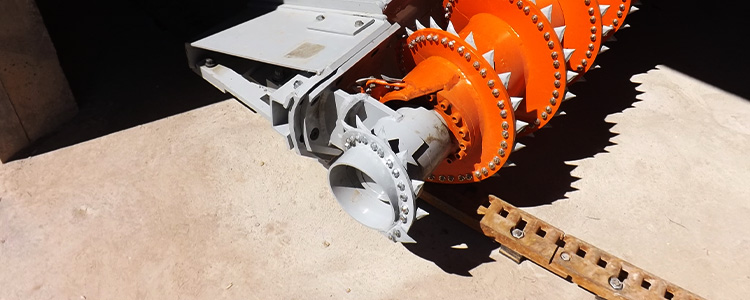

Our uniquely designed reclaim augers rotate 360 degrees around the bottom of a silo or dome to provide consistent, first-in-first-out (FIFO) unloading. Laidig reclaim augers are also equipped with specially designed knives – securely bolted to the auger flighting – to help mitigate wear on the flighting, and to cut through and move the material to the center of the silo floor, and onto the next step in the material handling process. The use of knives are unique to biomass applications, and are an important feature of the Laidig reclaim systems.

Laidig reclaim systems can be installed into new flat and cone bottom structures or retrofitted into existing storage vessels supplying a wide range of storage and output capacities.