We Know Feed & Grain.

Laidig understands the challenges involved within the Feed & Grain industry, and works diligently with feed manufacturers and grain facilities to develop innovative ways of solving problems, including:

- Solutions to prevent bin hang-up.

- Providing reliable, automated meal reclaim.

- Creating a first-in-first-out inventory control for traceability (and feed quality).

- Increased operational flexibility through large-capacity storage of meals.

- Reduced need for manpower.

- Improved operator safety.

- Helping to control environmental issues.

Laidig’s designs are a critical component to the success of modern-day feed mills.

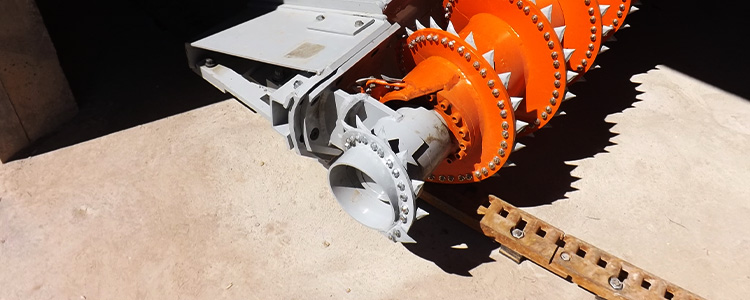

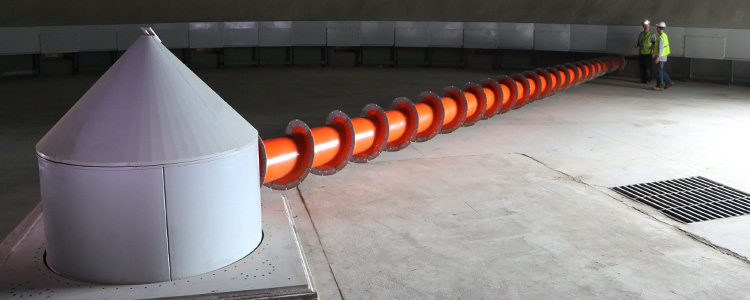

Laidig offers bulk storage silo and reclaim systems for cone-bottom and flat-bottom silos, while also offering automated cleanout of whole grains with zero bin entry. Each one is customized specifically to meet the needs and requirements of the materials they are handling.

Known throughout the Feed and Grain industry for our rugged, high-quality reclaim systems, Laidig excels in innovative, effective designs customized to store and reclaim materials with special handling requirements. Such materials include: soybean meal, canola meal, dried distillers grains (DDGS), wheat bran, rice bran, other grain meals, and whole grains.

Laidig has designed and engineered a family of silo bottom reclaim systems which offer proven performance and reliability for flat-bottom applications ranging between 2–45 meters in diameter, and cone-bottom applications ranging between 2–13 meters in diameter.